R&M Fiber Optic Cable 12 core OM4, green, Dca R855625

- Brand: R&M

- Product Code: R855625

- Availability: In Stock

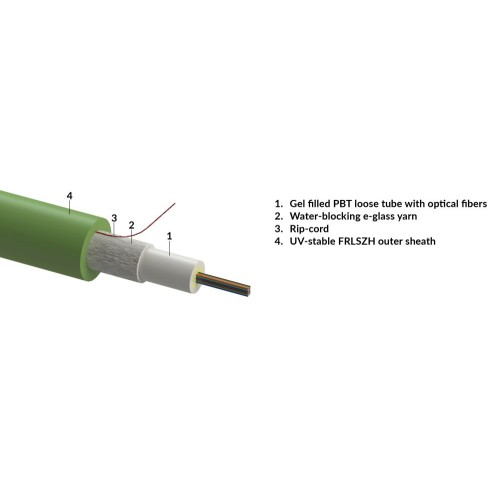

Central loose tube, single sheathed cable, iRP-increased rodent protected, universal-use, UV.FRLSZH sheath - green, Dca, 01 x 12 fibers OM4

Technical Data

| Cable family code | UT1GF |

| Cable type | Central loose tube cable |

| Cable version | n.a. |

| Cable application | universal use |

| CPR classification | Dca-s2,d1,a1 |

| DoP number | D9013 |

| Fiber type | OM4 |

| Fiber count | 12 |

| Fiber color coding | 1.-12.: red, green, blue, yellow, white, grey, brown, violet, turquoise, black, orange, pink |

| Fiber count per tube | 12 |

| Loose tube count | 1 |

| Loose tube diameter | 2.3 mm |

| Armor | Intensified rodent protection |

| Outer sheath thickness | 1.1 mm |

| Outer sheath material | UV stable FRLSZH |

| Outer sheath color | green |

| Cable outer diameter | 6.2 mm |

| Cable weight | 45.0 kg/km / 30 lbs/1000ft |

| DIN / VDE 0888 code | U-DQ(ZN)BH |

| CPR test method | EN 50575, EN 13501-6 |

| Standard put-up length on drum | 2100 m ± 5% |

| CPR classification | Dca |

Mechanical Data

| In-service tensile strength | 600 N |

| In-service tensile strength acceptance criteria | Δα ≤ 0,05 dB |

| In-service tensile strength test method | IEC 60794-1-21:E1 |

| Installation tensile strength | 1800 N |

| Installation tensile strength acceptance criteria | Δα ≤ 0,05 dB after test |

| Installation tensile strength test method | IEC 60794-1-21:E1 |

| Crush resistance long term | 1000 N/100mm |

| Long-term crush resistance acceptance criteria | Δα ≤ 0,05 dB prior release, no damage |

| Long-term crush resistance test method | IEC 60794-1-21:E3A |

| Short-term crush resistance | 2000 N/100mm |

| Short-term crush resistance acceptance criteria | Δα ≤ 0,05 dB after release, no damage |

| Short-term crush resistance test method | IEC 60794-1-21:E3A |

| Impact resistance | 10 Nm, 3 impacts, d=20 mm, R=300 mm |

| Impact resistance acceptance criteria | Δα ≤ 0,05 dB after test, no damage |

| Impact resistance test method | IEC 60794-1-21:E4 |

| Torsion | L = 1 m, rotation angle ±180°, 10 cycles |

| Torsion acceptance criteria | no damage |

| Torsion test method | IEC 60794-1-21:E7 |

| Repeated bending | R=20 x cable diameter, 25 cycles |

| Repeated bending acceptance criteria | no damage |

| Repeated bending test method | IEC 60794-1-21:E6 |

| Cable bend | d=20 x cable diameter, 4 turns, 3 cycles |

| Cable bend acceptance criteria | Δα ≤ 0,05 dB after test, no damage |

| Cable bend test method | IEC 60794-1-21:E11A |

| Minimum bend radius in service | 95 mm |

| Minimum bend radius during installation | 130 mm |

Environmental Characteristics

| Temperature cycling | -30 °C 70 °C / -22 °F +158 °F |

| Temperature cycling acceptance criteria | Δα ≤ 0,15 dB, reversible |

| Temperature cycling test method | IEC 60794-1-22:F1 |

| Reversible temperature cycling | -35 °C 70 °C / -31 °F +158 °F |

| Reversible temperature cycling acceptance criteria | Δα ≤ 0,05 dB after test |

| Reversible temperature cycling test method | IEC 60794-1-22:F1 |

| Operation temperature | -30 °C to 70 °C / -22 °F to +158 °F |

| Storage / Transport temperature | -35 °C to 70 °C / -31 °F to +158 °F |

| Thermal load | 0.59 MJ/m |

| Flammability vertical single cable | Pass |

| Flammability vertical single cable test method | IEC 60332-1-2 |

| Flammability vertical cable bundle | Pass |

| Flammability vertical cable bundle test method | IEC 60332-3-22 |